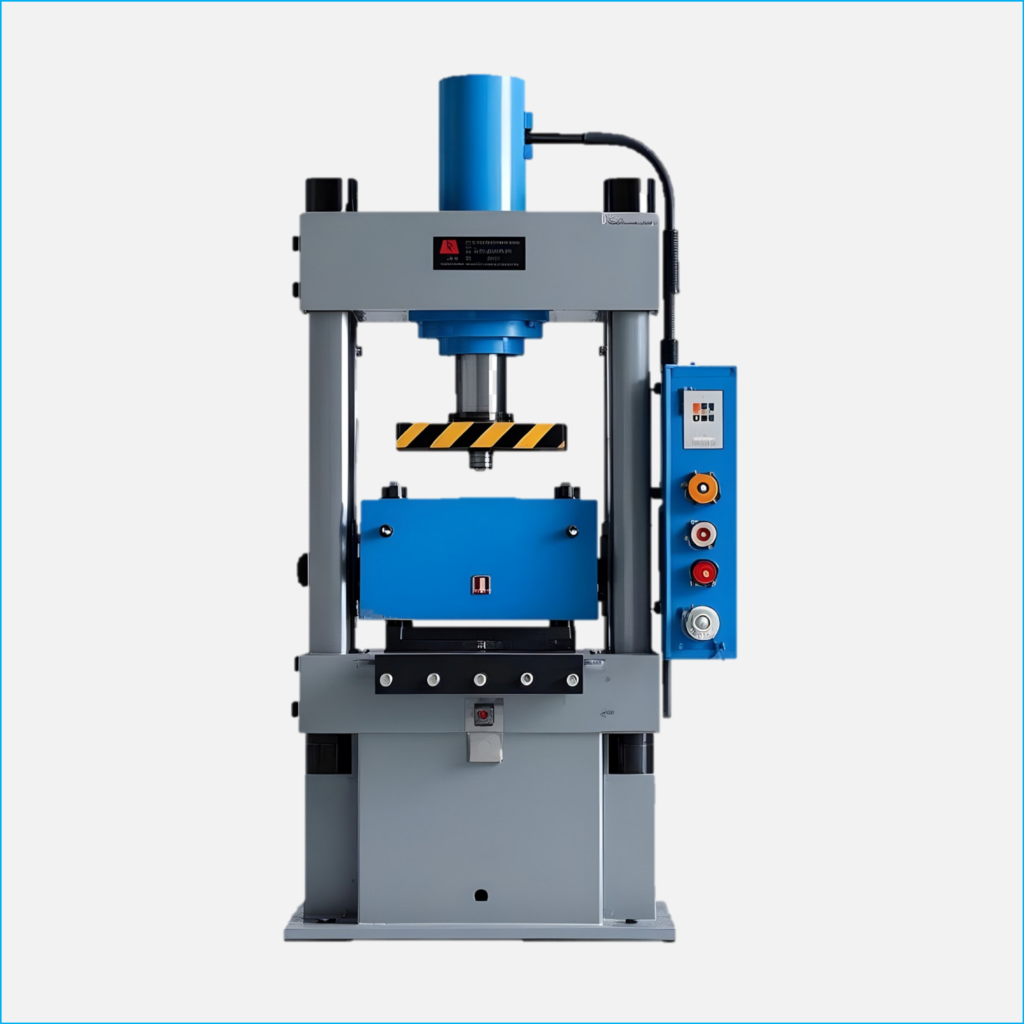

Hydraulic Press

Our Hydraulic Presses are engineered for the most demanding industrial forming applications, delivering immense force, precision control, and reliability. With capacities ranging up to 3500 metric tons (MT), these presses are ideal for heavy-duty forming, molding, stamping, forging, and deep drawing operations across multiple industries.

Technical Specifications:

Capacity Range: 100 MT to 3500 MT (customized as per requirement)

Frame Type: H-frame, C-frame, 4-pillar, or custom structural designs

Stroke Length: Up to 2000 mm

Daylight Opening: Up to 3000 mm

Table Size: Customizable up to 4000 mm x 4000 mm

Working Pressure: Up to 5000 PSI (350 bar)

Power Pack: Integrated high-pressure hydraulic power unit with advanced control features

Control System: PLC-based or manual with HMI/touchscreen for process monitoring and parameter control

Speed Options: Variable speed for pressing, return, and approach motions

Safety Features: Light curtains, pressure relief valves, emergency stop systems, and interlocks

Key Features:

Heavy-Duty Construction: Built with robust welded steel structure to withstand extreme forces and continuous operations

High Precision & Repeatability: Advanced hydraulic system ensures consistent pressure and speed control

Custom Engineering: Fully customizable based on specific process and application requirements

Energy Efficient: Hydraulic power pack designed for optimal energy usage with minimal heat generation

Smart Control System: PLC and HMI integration for real-time diagnostics, cycle programming, and error tracking

- Safety Assured: Built-in safety systems and interlocks to protect operators and machinery

Low Maintenance: Designed for longevity with easily replaceable components and minimal downtime

Applications:

Metal Forming & Fabrication: Bending, punching, blanking, and drawing of heavy steel and alloy components

Automotive Industry: Deep drawing of body parts, axle pressing, and sub-frame forming

Forging & Molding: Forging of high-strength parts and molding of rubber, plastic, or composite materials

Aerospace & Defense: Forming precision structural components with high tonnage requirements

Electrical & Transformer Manufacturing: Pressing of core laminations and structural frames

Construction Equipment Manufacturing: Shaping and forming of high-strength steel components

Appliance Industry: Stamping and forming of sheet metal for home and industrial appliances